ATELIER DE BEAULIEU

50 years //

Since 1971, L’Atelier de Beaulieu has been producing and marketing a wide range of capping endpieces, grips, sleeves and caps providing solutions for most of the problems of capping, masking, sealing, etc.

Our position as a subcontractor requires us to work in all sectors:

industry, paramedical, agricultural equipment, as well as the automotive, aeronautical, construction, childcare, sports and electronics industries, etc.

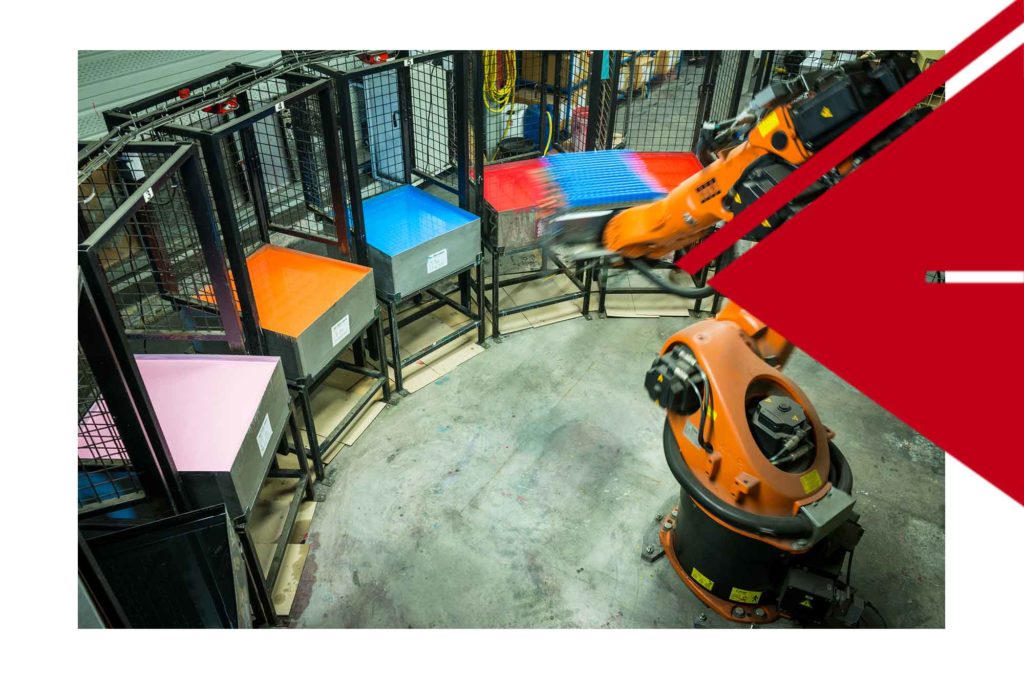

The diversity of our production facilities (manual and robotised), allows us to meet all your needs:

from single parts to medium-scale and large-scale production.

Our priority: our customers’ satisfaction.

We are constantly improving our production tool and our know-how in order to respond ever more quickly to our customers’ needs with the best possible quality

Quality

We are committed to a process of continuous improvement of our products, from design to delivery.

Our strengths

50 years of continuous development, with responsiveness provided by the automation of our entire workshop and round-the clock production. Our lead time for manufacturing tools is less than 4 weeks.

ATELIER DE BEAULIEU

PLASTI TREMP //

On 1st January 2014, l’Atelier de Beaulieu became a subsidiary of Plasti Tremp.

L’Atelier de Beaulieu and Plasti Tremp have a shared know-how and technical proficiency infused with a solid industrial heritage. Each product is the result of extensive expertise, ensuring impeccable quality and meeting the most stringent standards and user requirements.

Complementary products – common values:

By adopting a joint commercial policy, L’Atelier de Beaulieu and Plasti Tremp provide a global response through a complementary, coherent product offer.

A common goal: customer satisfaction

• Transformation of Plastics by PVC Plastisol Dipping and Injection

• Free study and quotation

• From the prototype to mass production

• Samples on request

• Wide choice of colours

• Mono-, bi or tri-colour parts

• Customisation through laser marking

• Digital printing

• 3D printing

• Various surface appearances

TRANSFORMATION OF PLASTIC MATERIALS

Plastisol dipping

Technical parts

Laser and digital marking

Endpieces and grips

Plastic injection

3D printing

Coating on metal or glass